Dunnet Bay Distillers

Developing lightweight recyclable packaging for a craft spirits company

Tags

Scotland was one of the first countries to adopt the Global Goals for Sustainable Development, setting a standard for national businesses to follow. Dunnet Bay Distillers, a Scottish distillery that makes the award-winning Rock Rose Gin, wanted to reduce its environmental footprint as it grew its business. Here’s how we helped develop recyclable spirits packaging that eradicates the need to use a single use bottle and also reduces costs.

Key successes

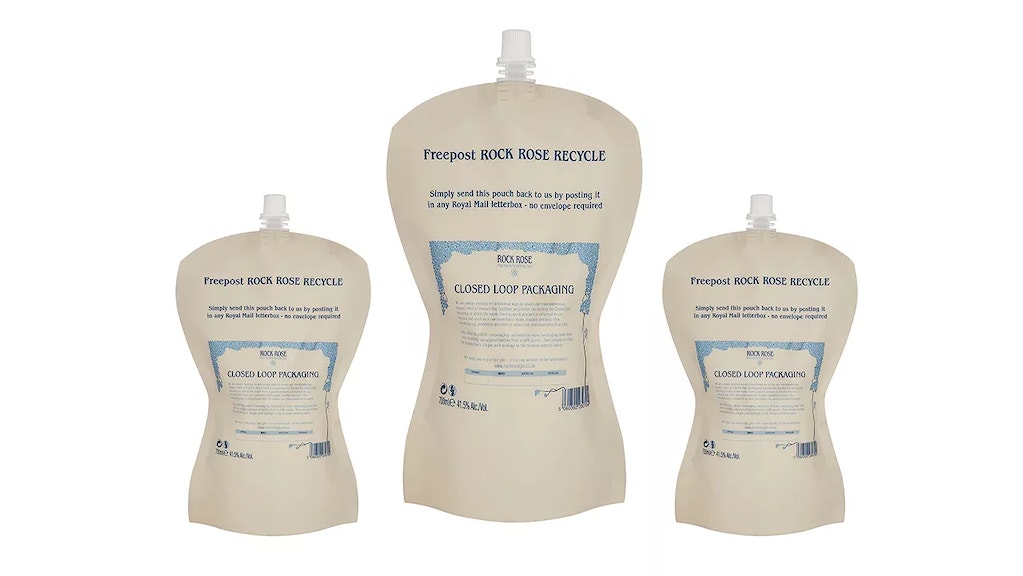

- Packaged 700 ml of gin and vodka in a lightweight recyclable foil pouch returnable by UK post

- Decreased packaging weight from 750 grams to 12.6 grams, a 98.3 per cent reduction in weight

- Reduced the distillery’s packaging and shipping costs by £10.20 on every case sent out

Creating sustainable packaging is good business

Scottish entrepreneurs Martin and Claire Murray have created a unique product, Rock Rose Gin, which has won awards and a devoted following for its botanicals-infused flavours. The premium gin is packaged in attractive, heavy ceramic bottles that are expensive to ship. However, the Murrays wanted to expand their gin and vodka business in the UK and enter the US market and needed lighter packaging.

“The craft spirits market is growing globally, with demand driven by the US and UK. In the UK, gin has overtaken prosecco as the most favoured-drink,” says Martin Murray, co-owner of Dunnet Bay Distillers. “We sought PA’s help to expand our share in this competitive market with a lower-cost recyclable packaging solution for Rose Rock Gin.”

Environmentally friendly packaging would help Dunnet Bay Distillers reduce storage and shipping costs to both the UK and US markets. It also would help the distillery stand out in the crowded craft spirits market.

“Sustainability is part of our brand and influences how we handle both production and packaging,” says Martin Murray. “We partnered with PA, because we knew that the company could help us create environmentally friendly packaging that also delivered real value to our distillery and our customers.”

“Flat, multi-layer pouches are a great way to ship alcohol and keep it from evaporating. However, they have traditionally been put into waste streams because of their recycling complexity,” says Ryan McGinley, PA industrial design expert.

Finding a recycling partner helped Dunnet Bay Distillers offer closed-loop packaging to meet its sustainability goals.”

Creating packaging solution that yields business value

We first made contact with the Murrays and Rock Rose Gin when we delivered an advice case as part of our framework for growth and development, in conjunction with Highlands and Islands Enterprise, the Scottish Government's economic and community development agency.

We worked closely with the Murrays to redesign their business by creating a network that would enable closed-loop packaging, where all packaging is reused, recycled or composted. First, we needed to create a lightweight pouch packaging solution that would be recyclable. We began by performing an IP landscape analysis to understand what manufacturers had created, to avoid designing against trademarks. Next, we explored different multi-layer laminates that could hold gin and vodka, settling on laminate material that was recyclable.

“We wanted users to be able to quickly decant the pack direct into the original gin bottle – then simply post it back to Dunnet for recycling collection,” says Ryan McGinley. “Any time you introduce significant change, it has to be as easy as possible for users to adopt new processes, or abandonment risk increases.”

Martin asked us to find a recycling partner before proceeding to design. Our research produced a number of potential partners. However, Terracycle was the best option for recycling multi-layer laminate. The next challenge was how to get used pouches back to the distillery for collection. Martin led negotiations with the Royal Mail service, winning agreement that customers could simply return empty packages, without envelopes, by placing them in UK post boxes. The pouches would then be sent en masse to the recycler.

Setting a new standard for sustainable packaging

Next, the joint team explored new pouch forms and openings, digitally modelling forms and prototyping two options: a pouch with a tear-off top and no plastic spout insert and a traditional spouted twist-top package. We produced prototypes of the two lead designs that Martin showed to some of his close customers in Scotland. Martin selected the twist-top package, as it was much easier to use when decanting the gin into existing ceramic bottles. Our team included an applied scientist, industrial designer, and a design strategist, and the time to initial prototyping took just two months.

Dunnet Bay Distillers’ new packaging ensures pouches will be transformed into plastic pellets and upcycled into new products, rather than end up in landfill. And they provide customers with a bottle for life. The distillery is delivering a positive human future for the spirits industry by setting a new standard for sustainable spirits packaging.

PA provided me with turnkey services, including a landscape IP scan, packaging prototypes and design, and recycling partner, which I couldn’t have obtained from a smaller design agency. This approach also made it incredibly easy and efficient to work with them.”

Explore more