Legrand Pop-Out

Engineering an elegant, retractable wall outlet

Tags

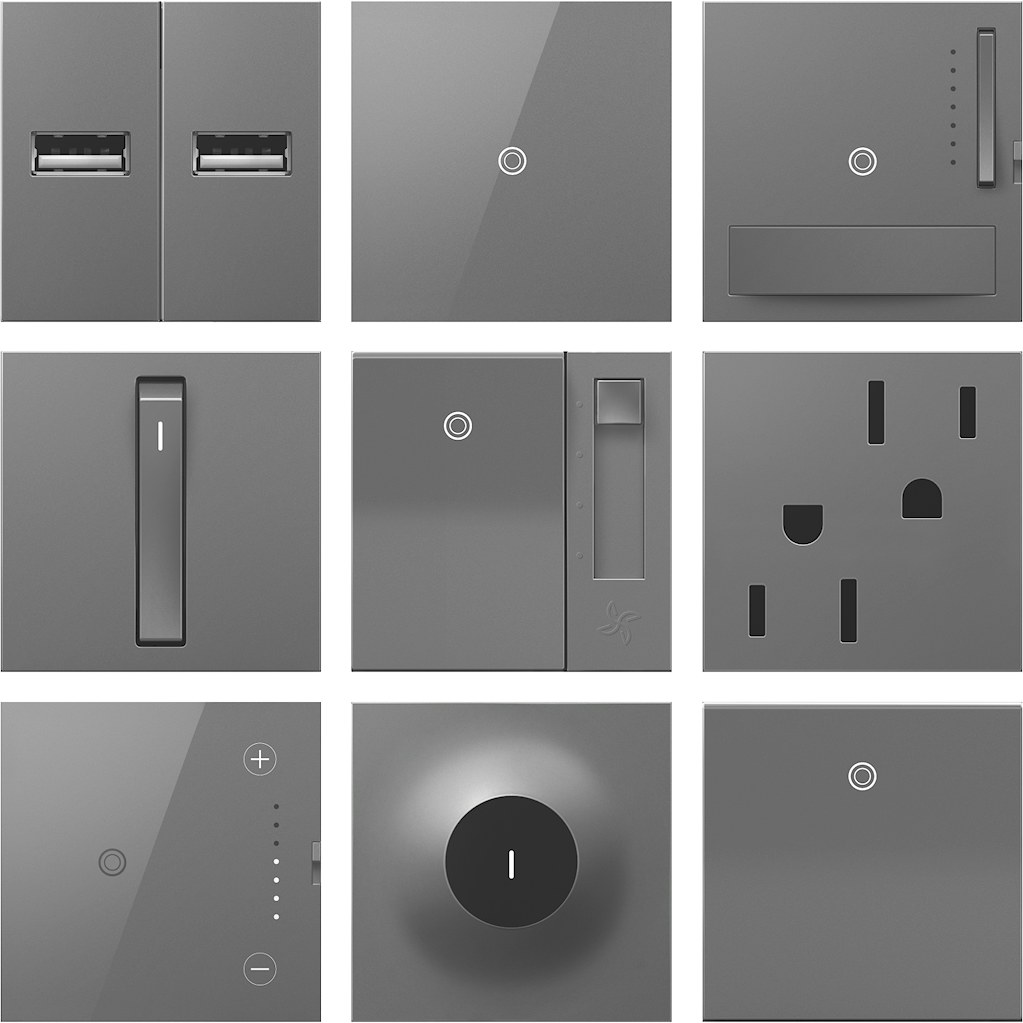

Legrand, in collaboration with our team, was in the process of developing a line of products, including switches, outlets, and lighting solutions, to upgrade electrical components in higher-end homes. Working with our industrial design team, they developed a concept for an electrical outlet that retracted into the wall for superior aesthetics and safety and included three ports instead of the standard two.

To make their design viable, they needed to address mechanical and electrical requirements to meet regulatory compliance standards, as well as solve for Design for Manufacturing and Assembly (DFMA) challenges. When Legrand reached out to us to engineer their concept, we were intrigued by its innovative design, but foresaw challenges posed by regulatory constraints. With no immediate picture of how to solve the problem at hand, we were excited to try and figure it out.

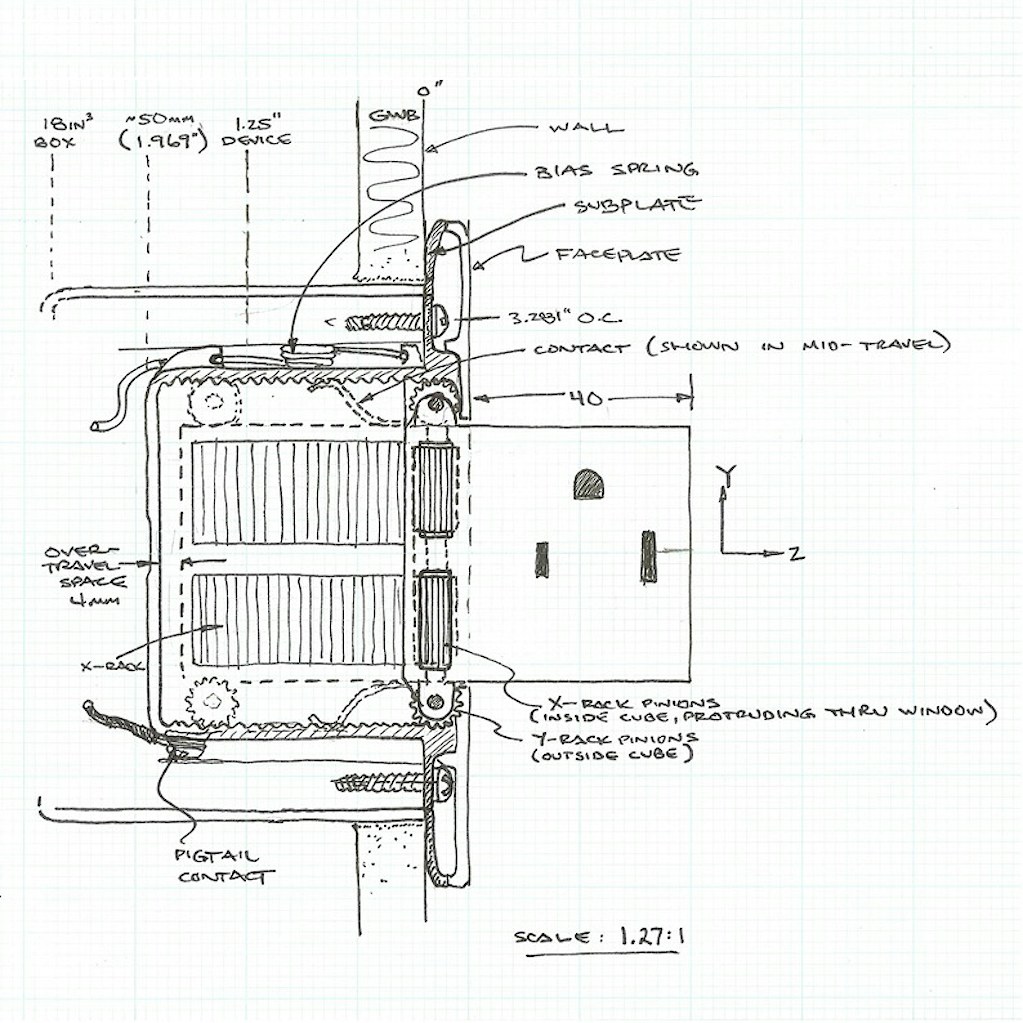

The Pop-Out component needed to smoothly glide in and out from the wall and stay securely in position when retracted or expanded, which would require a mechanism to move the piece in a controlled, predictable manner and lock in place. To meet regulations, it also had to be strong enough to support a 70 lb weight without breaking, in case a child were to step on the extended outlet.

Furthermore, standard electrical wiring wasn’t designed to move back and forth, so code wouldn’t allow a design that required this to happen. Therefore, the solution would need to reconcile the Pop-Out’s dynamic design with fixed electrical wiring.

What made the above requirements especially ambitious was that the entire mechanism needed to fit within a compact, standard electrical box.

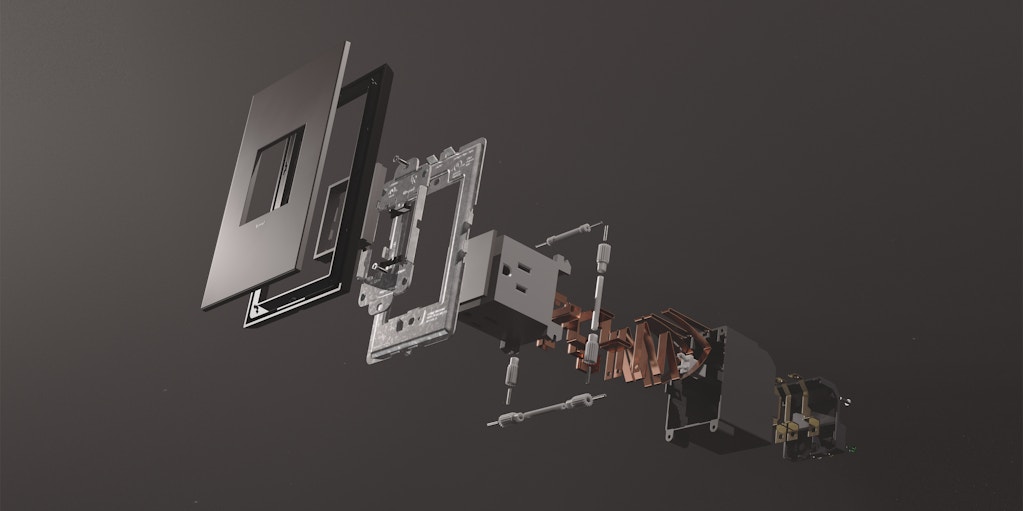

A rack-and-pinion system guides the Pop-Out as it travels in and out, and a push-push latching mechanism keeps it locked in the selected position. The paired rack-and-pinion sets on all four sides of the box are a space-efficient solution that allows for a smooth and satisfying push, while also providing enough strength and friction to withstand the weight requirement.

We envisioned a set of springs that could provide the force needed and also conduct electricity from the main electrical wiring to the outlets. We determined that using beryllium copper in a precisely engineered design could achieve both of these goals and enable sufficient dissipation of heat even under full electrical load.

The result was an elegantly engineered, patented solution that met cost and manufacturing considerations while satisfying UL and other regulatory requirements. The Pop-Out has been successfully launched in the market and has been well-reviewed by designers and architects for its innovative design.

Explore more