The water industry in a hydrogen economy

Tags

This article was first published in The Water Report

The UK Government has committed to Net Zero carbon emissions by 2050 (2045 in Scotland) and is due to set into law the world’s most ambitious climate change target, cutting emissions by 78% by 2035 in comparison to levels in 1990. Over the last few months, the 10 Point Plan and the Energy White Paper have begun to paint some of the broad brushstrokes of the path to Net Zero. Hydrogen is a key feature of both. Hydrogen offers ways to decarbonise by at least partially replacing fossil-based fuels in the automotive, maritime and aviation sector. It can also replace natural gas in some industrial processes and can be used in heating for some commercial and residential housing stock.

However, a future hydrogen economy could also have an impact on the water industry. Water UK’s Net Zero 2030 Roadmap stated that ‘if hydrogen emerges as an alternative fuel then water demand would increase 15-20%’. This raises significant issues for the sector. Firstly, in many areas of the country, water is already scarce and will become scarcer with the continued onset of climate change – how will water for hydrogen be sourced? Secondly, how does the sector plan for this? This would create a significant cross-sector dependency, with the need to work tightly with other areas of government, regulators and industry to ensure water supply was available in the right place at the right time and in the right amounts.

These are important questions for the sector and to address them, the sector needs to understand the different types of hydrogen, the high-level scenarios for hydrogen, the impact that would have on the water industry and the practical evolution of hydrogen.

Types of hydrogen

The impact on the water industry will depend on the type of hydrogen and the extent of its applications, as differing hydrogen production technologies require different amounts of water. We set out below the technologies used to produce ‘clean’ hydrogen with no or low CO2 emissions, as these are most likely to be adopted.

Water electrolysis: Depending on the source of electricity used, there are multiple types/colours of hydrogen:

- Green: This is the ‘cleanest’ form of hydrogen, with no harmful greenhouse gas emissions, made via electrolysis using clean electricity from surplus renewable energy sources, such as solar or wind.

- Pink: In this case electrolysis is powered by nuclear energy.

- Yellow: hydrogen made through electrolysis with solar power, or power of mixed origin

Electrolyser systems split demineralised water into hydrogen and oxygen. These systems are composed of an electrolyser stack and the balance of plant (power supply, water supply, water purification, and hydrogen compression and processing where needed). Currently, there are two dominant electrolysers commercially available, Alkaline and Proton Electron Membrane (PEM). Water use is between 9-14 kg (depending on the amount of demineralisation required) per kg of hydrogen produced.

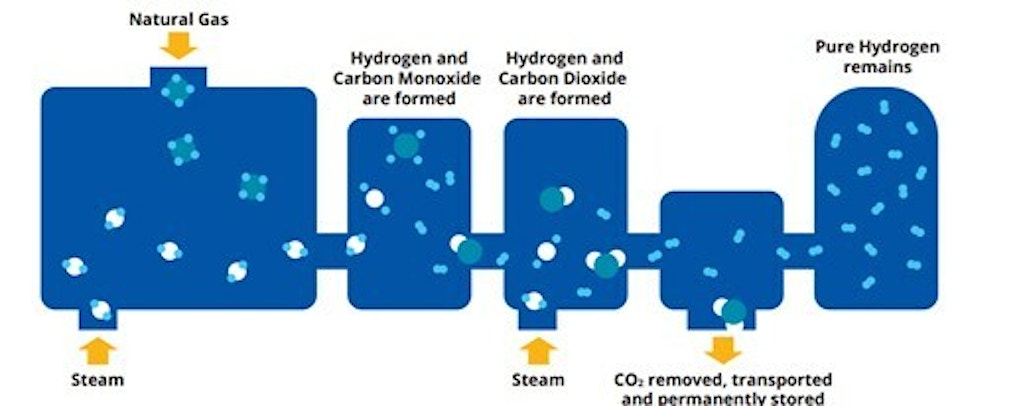

Natural Gas reforming +CCUS or gasification + CCUS: Hydrogen produced with this method is characterised as blue.The process uses fossil fuels, but the intention is to capture the carbon (CCS) from the process, as shown in the figure below. There are two primary process options: Steam Methane Reforming (SMR) or Autothermal Reforming (ATR). SMR is a mature production process in which high-temperature steam (700°C–1,000°C) is used to produce hydrogen from a methane source, such as natural gas. Water use is between 6-13 kg per kg of hydrogen produced. Water consumed in the chemical process is below 8 kg for ATR, but this hydrogen production method has not yet been deployed at scale.

Source: ATCO

Scenarios for hydrogen and impact on the water industry

Below we have used two respected sources for scenarios for Net Zero and the energy transition to determine potential usage of hydrogen and impact on the water industry. These are the National Grid’s Future Energy Scenarios (NG FES) and the Committee for Climate Change’s (CCC) 6th Carbon Budget. The NG FES, set out three scenarios to meet Net Zero: Consumer transformation (CT), System transformation (ST) and Leading the Way (LW)¹. The CCC sets out several scenarios - we have used the central ‘Balanced Pathway’ scenario. These yield the demand for hydrogen set out in the table below.

These scenarios can be used to derive requirements for water as set out below in the graphs where we present CCC’s central scenario and National Grid’s System Transformation, which has the highest hydrogen demand³.

Figure 1: Water supply demand for hydrogen production per decarbonisation scenario and generation technology, (Left – CCC Balanced Pathways, Right – National Grid FES System Transformation)

These graphs show that, there are scenarios where c. 5% of the annual public water supply will be required to support the forecast hydrogen demand. This would have the same impact on drinking water demand as adding an additional 3.3 million people to UK’s population. The UK drinking water supply is estimated at c.5,000 MT per year⁴. This pre-supposes that water itself does not become scarcer and also assumes the extensive use of ATR, if this does not prove feasible then the percentage will be far higher. Further, there is likely to be a strong regional concentration of hydrogen demand and production in some areas. These, and other, factors yield the potential 15-20% cited by Water UK.

Practical evolution of hydrogen

This is a very structured approach and the reality will be far more complex and nuanced. We need to consider how hydrogen may be rolled-out in practice and where water may be sourced from.

There is a lot of variation between the scenarios on the adoption of hydrogen and the level of electrification. For example, the ST scenario has the most significant hydrogen demand, driven by the use of hydrogen for residential heating, with the whole of the existing gas network repurposed to supply hydrogen to households. There are however significant challenges with this approach. Firstly, it would require a massive expansion in renewable generation, which may not be achievable and, if it were achieved, could potentially be used for generating heat through electricity rather than an intermediate step of producing hydrogen. Secondly, the cost of hydrogen production and hydrogen is high – re-purposing the gas grid is likely to be prohibitively expensive. In practice, it is easier to move electrons rather than hydrogen molecules to the point of consumption.

An alternative scenario for hydrogen is that it will develop in a more distributed, clustered infrastructure. The size and modularity of the existing technology means that it can be scaled accordingly and produced close to the point of consumption. Therefore, there will be opportunities for end-to-end hub supply chain decarbonisation. Together with emerging localised hydrogen production in dispersed sites, aggregated hubs may develop. Locally produced hydrogen could be deployed not only as a fuel for industrial activity (i.e. cement, glass, oil refining), but also for onsite ground service vehicles and operational fleet servicing hubs.

This clustered hub approach would reduce overall impact on the water industry but could create a more localised and aggravated effect. In North East England, for example, several companies, including BP, Equinor and Uniper, have announced blue hydrogen production sites, concentrated in a relatively narrow region. One of these hydrogen projects alone could add up to 3.2 MT to the regional water demand per year.

The second aspect of hydrogen evolution is how the water may be sourced. There are alternatives to the use of drinking water. One option could be water sourced from desalination plants. This is a sustainable way to source water but bears very high operational costs and requires significant cost efficiencies before becoming a commercially viable solution. It will also be restrictive in terms of location. For example, in the south-east, the Environment Agency is currently restricting/reducing current licences for new abstractions and there are few viable locations for desalination of any scale due to the many protected marine environments and insufficient marine hydrology to disperse the waste hyper-brine.

A second option is to use recycled water sourced from wastewater treatment plants. The prevalence of wastewater facilities across the country, combined with the clustered infrastructure approach described above could offer flexible siting options and sustainable hydrogen production.

Wastewater streams could also become valuable as an alternative production method. Water companies are sitting on a wealth of hydrogen in the form of ammonia in their wastewater streams; this could be used for hydrogen production through catalytic cracking. High level estimates suggest at least 18,000 tonnes of hydrogen could be produced via this method each year and the potential could be double this. However, this would need to comply with CSMG legislation which requires wastewater discharges to pass back to the environment to maintain existing water supplies and ecosystems.

Conclusions

The UK has made a bold commitment to Net Zero, but the path is unclear. Many potential paths could have a significant impact on the water industry. The extent of hydrogen usage is one factor affecting the industry. An initial assessment suggests that the impact of hydrogen is more likely to be at a regional and local level than at a national level, but it is important for the industry to monitor the evolution of government policy and commercial development in this area.

The examination of hydrogen does emphasise the extent to which Net Zero cuts across existing industries, commerce, government departments and regulators. Within this, there needs to be clarity on where the policy responsibility for hydrogen sits and how that is managed through cross-organisation governance, as Hydrogen will require decisions on the balance between the water industry, the energy industry, the environment and the industrial and commercial sector. The water industry must ensure it is involved in appropriate governance with these stakeholders.

There will also be policy decisions on how hydrogen is managed within the sector itself, for example should this be a feature of the non-household market. Hydrogen needs to feature in national and regional planning and the industry needs to discuss with Ofwat how the potential for hydrogen should start to be recognised in PR24.

There is an exciting future for hydrogen in the UK’s Net Zero strategy; the water industry must be a part of the evolve strategy to ensure a successful rollout.

¹ https://www.nationalgrideso.com/document/173821/download

² Assuming energy density of 1 kg hydrogen equals to 33.6 kWh of usable energy

³ Values shown in the graphs reflect the upper range of water requirement per kg of hydrogen produced

⁴ https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/785567/Water_Abstraction_Statistics_England_2000_2017_Final.pdf

Explore more